GB /T 1563 - 2017

楔键用键槽

GB /T 6188 - 2017

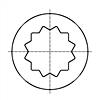

螺栓和螺钉用内六角花形

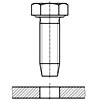

GB /T 2 - 2016

紧固件 - 外螺纹零件末端 (ISO 4753:2011, MOD)

GB /T 3106 - 2016

紧固件 - 螺栓、螺钉和螺柱 - 公称长度和螺纹长度 (ISO 888:2012, MOD)

GB /T 152.2 - 2014

沉头螺钉用沉孔

GB /T 13807.1 - 2008

腰状杆螺柱连接副 型式分类

GB /T 5652 - 2008

扩口式管接头扩口端尺寸

GB /T 6188 - 2008

螺栓和螺钉用内六角花形

GB /T 6403.3 - 2008

滚花(直纹滚花和网纹滚花)

GB /T 20330 - 2006

攻丝前钻孔用麻花钻直径

GB /T 1095 - 2003

平键 键槽的剖面尺寸

GB /T 1098 - 2003

半圆键 键槽的剖面尺寸

GB /T 3105 - 2002

普通螺栓和螺钉 - 头下圆角半径

GB /T 145 - 2001

中心孔

GB 18194 - 2000

铆钉杆径 (不适用于抽芯铆钉) [ISO 1051:1999]

GB /T 16823.1 - 1997

螺纹紧固件应力截面积和承载面积

GB /T 5279.2 - 1997

沉头螺钉 第2部分 十字槽插入深度

GB /T 12520 - 1990

沉头(盘头、圆头等)用高扭矩十字槽

GB 152.1 - 1988

铆钉用通孔

GB 707 - 1988

热轧槽钢

GB 6189 - 1986

紧固件用六角花形—E型

GB 5277 - 1985

紧固件 螺栓和螺钉通孔

GB 5278 - 1985

紧固件 - 开口销孔和金属丝孔 (ISO 7378:1983)

GB /T 5279 - 1985

沉头螺钉头部配置和测量

GB 944.1 - 1985

螺钉用十字槽

GB 3104 - 1982

紧固件 - 六角产品的对边宽度

GB 3105 - 1982 (R1988)

螺栓和螺钉的头下圆角半径

DIN 7500 (-2) - 2016

用于公制ISO螺纹的自攻螺钉- 第2部分:孔直径的指导值

DIN 76-1 - 2016

螺纹收尾及退刀槽

DIN 7975 - 2016

自攻螺钉安装用孔(底孔)的直径及拧紧力矩

DIN 34824 - 2007

螺栓和螺钉用内十二角槽

DIN 332 (-1) - 1986

60° 中心孔 - R 型, A 型, B 型 与 C 型

DIN 7500-2 - 1984

米制三角锁紧螺纹安装用光孔尺寸

DIN 78 - 1983

外螺纹零件末端形式

DIN 82 - 1973

滚花

ISO 6149-1 - 2022

液压传动和通用连接件.ISO 261米制螺纹和O形密封圈的端口和螺柱端.第1部分:O形密封圈用带截短外壳的端口

ISO 10664 - 2014

内六角梅花槽

ISO 1179-1 - 2013

通用和液压传动用连接件 带弹性体密封或金属对金属密封的ISO 228-1标准螺纹的孔口和螺柱端 第1部分:带螺纹的孔口

ISO 13444 - 2012

滚花尺寸和指示

ISO 4753 - 2011

紧固件 ISO米制外螺纹零件的末端

ISO 1179-4 - 2007

通用和液压传动用连接件.带弹性体密封件或金属对金属密封件的ISO 228-1螺纹开口和螺柱端头.第4部分:通用只带金属对金属密封件(B型)的螺柱端头

ISO 10664 - 2005

内六角梅花槽

ISO 1302 - 2002

产品几何技术规范(GPS)技术产品文件中表面结构的表示法

ISO 885 - 2000

普通螺栓和螺钉. 米制系列. 头下圆角半径

ISO 1051 - 1999

铆钉杆直径

ISO 7403 - 1998

航空航天 花键传动 扳手结构 米制系列

ISO 9974-1 - 1996

通用和液压传动用联接件 带ISO 261弹性螺纹或金属-金属密封的气门和双头螺栓端头 第1部分:螺纹气门

ISO 9974-2 - 1996

通用和液压传动用联接件 带ISO 261弹性螺纹或金属-金属密封的气门和双头螺栓端头 第2部分:弹性密封的双头螺栓端头(E型)

ISO 9974-3 - 1996

通用和液压传动用联接件 带ISO 261弹性螺纹或金属-金属密封的气门和双头螺栓端头 第3部分:金属-金属密封的双头螺栓端头(B型)

ISO 11926-3 - 1995

通用和液压传动用联接件 带ISO 725螺纹和O形圈密封的油口和螺纹端头 第3部分:轻型(L系列)螺栓端头

ISO 6157-2 - 1995

紧固件--表面缺陷 Part2:螺母

ISO 7721-2 - 1990

沉头螺钉Part2:十字槽插入深度

ISO 6157-1 - 1988

紧固件. 表面缺陷Part1:螺栓、螺柱、螺钉和一般要求螺柱

ISO 6157-3 - 1988

紧固件. 表面缺陷 第3部分:螺栓, 螺钉和螺柱特殊要求

ISO 7994 - 1985

沉头(盘头、圆头等)用高扭矩十字槽

ISO 4755 - 1983

紧固件. ISO米制外螺纹用螺纹退刀槽

ISO 4757 - 1983

H型十字槽

ISO 4757 - 1983

Z型十字槽(米字槽)

ISO 7721 - 1983

沉头螺钉 - 头部形状和测量

ISO 272 - 1982

紧固件. 六角产品. 对边宽度

ISO 273 - 1979

紧固件. 螺栓和螺钉用通孔

ISO 3508 - 1976

符合ISO 261 和ISO 262 螺纹的紧固件用螺纹收尾

ISO 274 - 1975

圆形截面铜管尺寸

JIS B 1015 - 2018

螺栓和螺钉用内六角花形

JIS B 1082 - 2009

紧固件的应力区和承载区

JIS B 1005 - 2003

普通螺栓和螺钉 米制系列 头下圆角半径

JIS B 1603 - 1995

渐开线花键齿面啮合 一般事项,各种要素及检验

JIS B 0951 - 1962

滚花

JB /T 4024 - 2014

自动冷镦机 模腔尺寸

JB /ZQ 4247 - 2006

普通螺纹 内、外螺纹余留长度,钻孔余留深度,螺栓突出螺母的末端长度

JB /T 6960 - 1993

铝型材挤压模结构与技术条件

![82°沉头螺钉的凹槽型式 [Table 2]](https://imgcc.164580.com/upload/48/standard/2018/09/11/1536630391295096012.jpg)

ASME/ANSI B 18.6.3 (T2) - 2013

82°沉头螺钉的凹槽型式 [Table 2]

![BF型 BT型 自切自攻螺钉螺纹和末端 [Table 43]](https://imgcc.164580.com/upload/48/standard/2018/09/29/1538208543197073992.jpg)

ASME/ANSI B 18.6.3 (T43) - 2013

BF型 BT型 自切自攻螺钉螺纹和末端 [Table 43]

![D, F, G, T 型自攻螺钉 螺纹和末端 [Table 44]](https://imgcc.164580.com/upload/48/standard/2018/09/30/1538274982710145766.jpg)

ASME/ANSI B 18.6.3 (T44) - 2013

D, F, G, T 型自攻螺钉 螺纹和末端 [Table 44]

![自挤自攻 TRS型 螺纹和末端 [Table 45]](https://imgcc.164580.com/upload/48/standard/2018/10/08/1538974825207969765.jpg)

ASME/ANSI B 18.6.3 (T45) - 2013

自挤自攻 TRS型 螺纹和末端 [Table 45]

ASME/ANSI B 18.6.3 (T48) - 2013

自攻螺钉拧入性试验用标准试验板厚度和孔径 [Table 48]

ASME/ANSI B 18.6.3 - 2010

美制沉头螺钉用十字槽

ASME/ANSI B 18.6.3 - 2010

球面圆柱头螺钉用十字槽

ASME/ANSI B 18.17 - 1968 (R1983)

美制拇指螺钉、翼型螺钉末端型式

EN 10058 - 2018

一般用途热轧扁钢筋尺寸及形状和尺寸公差

EN 10131 - 2006

冷成形用冷轧无涂层、电镀锌或锌-镍涂层低碳高屈服强度扁平制品 — 外形和尺寸偏差

EN 3044 - 1998

航空航天系列 螺旋形线圈自锁式螺纹嵌镶件安装孔 设计标准

EN 27721 - 1991

沉头螺钉头部配置和测量

UNI 7345 - 1974

自攻铆钉 螺纹和末端

DIN EN 20273 - 1992

紧固件 螺栓和螺钉通孔

IS 7478 - 2011

十字槽

ASME B 18.6.3 (T4.11.1-1) - 2024

自攻螺钉拧入性试验用标准试验板厚度和孔径

ASME B 18.6.3 (T4.1.2.1-1) - 2024

BF型 BT型 自切自攻螺钉螺纹和末端

ASME B 18.6.3 (T4.1.2.2-1) - 2024

D, F, G, T 型自攻螺钉 螺纹和末端

ASME B 18.6.3 (T4.1.3-1) - 2024

自挤自攻 TRS型 螺纹和末端

ASME B 18.3 (Table 18) - 2012

内六角凹槽对边尺寸偏差 [Table 18]

![内凹槽螺钉无螺纹杆长和夹紧长度 [Table 4]](https://imgcc.164580.com/upload/48/pic/2021/05/27/1622102178590886964.jpg)

ASME B 18.3 (Table 4) - 2012

内凹槽螺钉无螺纹杆长和夹紧长度 [Table 4]

ASME B 18.6.5M - 2000 (R2010)

米制自攻螺钉用螺纹及末端型式

![BF型,BT型,自切自攻牙(螺纹切削自攻牙) [Table 7]](https://imgcc.164580.com/upload/48/standard/2020/06/05/1591322143016742879.jpg)

ASME B 18.6.4 (BF/BT) - 1998 (R2005)

BF型,BT型,自切自攻牙(螺纹切削自攻牙) [Table 7]

![D、F、G和T型,自切自攻牙(螺纹切削自攻牙)(统一螺纹) [Table 8]](https://imgcc.164580.com/upload/48/standard/2020/06/05/1591326271806674189.jpg)

ASME B 18.6.4 (D/F/G/T) - 1998 (R2005)

D、F、G和T型,自切自攻牙(螺纹切削自攻牙)(统一螺纹) [Table 8]

HB 0-9 - 2000

六角形螺纹零件保险孔

BS EN 3911 - 2010

航空航天系列.六瓣凹槽.尺寸和公差

BS EN 10241 (T6) - 2000

管件的螺纹端 表6