2. 表面缺陷的种类、原因、外观特征和极限

2.1 裂缝 Cracks

裂缝是一种清晰〈结晶体〉的沿金属晶粒边界或横穿晶粒的断裂,并可能含有外来元素的夹杂物。裂缝通常是金属在锻造或其他成型工序或热处理的过程中,由于受过高的应力而造成的,也可能在原材料中即存在裂缝。当工件被再次加热时,通常由于氧化皮的剥落而使裂缝变色。

2.1.1 淬火裂缝 Quench cracks

原 因 |

淬火裂缝通常是不规则相交、无规律方向的呈现在紧固件表面。 |

外 观 |

|

极 限 | 任何深度、任何长度或任何部位的淬火裂缝都不允许存在。 |

2.1.2 锻造裂缝和夹渣裂缝 Forging cracks and inclusion cracks

原 因 | 锻造裂缝可能在切料或锻造工序中产生,并位于螺母的顶面或底面上,或顶面(底面)与对边平面交接处,夹渣裂缝由原材料固有的非金属夹渣而造成。 |

外 观 |

|

极 限 |

a) 贯穿支承面的锻造裂缝不应多于两条,其深度也不得超过0.05D; b) 延伸到螺孔内的裂缝不应超出第一扣完整螺纹; c) 在第一扣完整螺纹上的裂缝深度不应超过0.5H1。 D——螺纹公称直径;H 1——螺纹实际牙高,H 1 = 0.541P;P——螺距。 |

2.1.3 全金属有效力矩型锁紧螺母的锁紧部分裂缝

Cracks in the locking element of all-metal prevailing torque type nuts

原 因 | 全金属有效力矩型锁紧螺母的锁紧部分裂缝,可能在切料或锻造或收口(压扁)过程中产生,并呈现在外部或内部表面上。 |

外 观 |

|

极 限 |

a)贯穿顶部圆周的裂缝不应多于两条,其深度也不得超过O.O5D; b)延伸到螺孔内的裂缝不应超出第一扣完整螺纹; c)在第一扣完整螺纹上的裂缝深度不应超过O.5H1。 由于收口(压扁)产生并位于锁紧部分的裂缝,应不允许。 D——螺纹公称直径; H 1——螺纹实际牙高,H 1 = 0.541P;P——螺距。 |

2.1.4 螺母-垫圈组合件的垫圈座裂缝 Cracks in the washer retainer of nuts with captive washers

垫圈座裂缝是将垫圈固定在螺母上的过程中,金属的边缘或凸起部分的开裂。

原 因 | 在装配垫圈的过程中,当压力施加到边缘或凸起部分时,可能产生垫圈座裂缝 |

外 观 |

|

极 限 | 垫圈座裂缝应控制在翻铆以后的边缘或凸起部分以内,并且垫圈应能自由转动,且不脱落。 |

2.2 剪切爆裂 Shear bursts

剪切爆裂是金属表面的开裂。

原 因 | 在锻造过程中可能产生剪切爆裂,如在螺母的外表面或在法兰面螺母的周边上出现。通常剪切爆裂和螺母轴心线约成45° |

外 观 |

|

极 限 | 位于螺母顶面或底面与对边平面交接处的剪切爆裂的宽度不得大于(0.25+0.02s)mm。 法兰面螺母的法兰圆周上的剪切爆裂,不应延伸到支承顶直径(dw)的最小尺寸内,其宽度也不得超过0.08dc; s——对边宽度;dc——法兰直径 |

2.3 爆裂 Bursts

爆裂是金属表面的开裂。

原 因 | 在锻造过程中,由于原材料的表面缺陷,可能产生爆裂,如在螺母的外表面或在法兰面螺母的周边上出现 |

外 观 |

|

极 限 |

对角上的爆裂,不应使对角宽度减小到低于规定的最小尺寸。 位于螺母顶面或底面与对边平面交接处的剪切爆裂的宽度不得大于(0.25+0.02s)mm。 法兰面螺母的法兰圆周上的爆裂,不应延伸到支承顶直径(dw)的最小尺寸内,其宽度也不得超过0.08dc; s——对边宽度;dc——法兰直径 |

2.4 裂纹 Seams

裂纹是材料上皱纹窄的开裂形成的纵向表面缺陷。

原 因 | 裂纹通常是制造紧固件的原材料中固有的缺陷 |

外 观 |

|

极 限 | 裂纹的深度对所有的螺纹规格均不得超过0.O5D 。 D—螺纹公称直径 |

2.5 皱纹 Folds

皱纹是在锻造过程中,呈现在螺母表面的金属折叠。

原 因 | 在锻造螺母的过程中,位于或接近直径(截面)变化的交接处,或螺母的顶面或底面。由于材料的位移可能产生皱纹 |

外 观 |

|

极 限 | 位于法兰面螺母的法兰圆周与支承面交接处的皱纹,不得延伸到支承面。其他皱纹允许存在。 |

2.6 凹痕 Voids

凹痕是在锻造或镦锻过程中,由于金属未填满而呈现在螺母表面上的浅坑或凹陷。

原 因 | 凹痕是由于切屑或剪切毛刺或原材料的锈层造成的痕迹或压印,并在锻造或镦锻工序中未能消除 |

外 观 |

|

极 限 | h≤0.02D或最大为0.25 mm。 凹痕的面积: 支承面上的凹痕面积之和,不应超过: 支承面总面积的5%,对螺纹公称直径D≤24 mm的螺母; 支承面总面积的10%,对螺纹公称直径D>24 mm的螺母。 D—螺纹公称直径 |

2.7 切痕 Tool marks

切痕是纵向或圆周方向浅的沟槽。

原 因 | 切痕因制造工具与工件之间的相对运动而产生 |

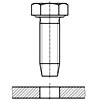

外 观 |

|

极 限 | 螺母支承面上的切痕,其表面粗糙度不应超过Ra=3.2μm(按GB/T 1031规定)。其他表面的切痕允许存在 |

2.8 损伤 Damages

损伤是指螺母任何表面上的刻痕。

原 因 | 损伤,如凹陷、擦伤、缺口和凿糟,因螺母在制造和运输过程中受外界影响而产生 |

外 观 | 没有准确的几何形状、位置或方向,也无法鉴别外部影响的因素 |

极 限 |

如有必要,按特殊协议,如包装要求,以避免运输中的损伤。 |

3. 检查与判定程序

使用以下程序应贯彻GB/T 90的有关规定。

3.1 常规验收检查

常规验收检查,应采用目测检查程序以确保产品符合本标准的规定。

3.2 非破坏性检查

按GB/T 90的规定,从验收批中抽取样本,并可放大10倍进行目测或其他非破坏性的检查,如用磁力技术或涡流电流。若发现由缺陷样品未超过允许的极限,则接受该批产品。如用户要求进行100%的全检,则应在订单中注明。

3.3 破坏性检查

在去除表面涂、镀层后,如发现有可能超过允许极限的表面缺陷,则应选取有最严重表面缺陷的样品进行破坏性试验(GB/T 3098.12和GB/T 3098.14)。

3.4 仲裁试验

由易切钢制造的螺母的仲裁检查,应按GB/T 3098.14对螺母进行扩孔实验。根据供需双方协议,可根据GB/T 3098.12进行附加试验。

3.5 判定

如果在目测检查中,发现淬火裂缝或在缩进部分有超差的裂缝,或超过尺寸极限的表面缺陷,则该批产品应予拒收。

如有任何样品未能通过按3.3条和3.4条进行的破坏性试验,则该批产品予以拒收。

Taper keys of keyways

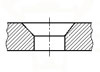

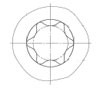

Hexalobular internal driving feature for bolts and screws

Fasteners-Ends of parts with external thread(ISO 4753:2011, MOD)

Fasteners - Bolts, screws and studs - Nominal lengths and thread lengths (ISO 888:2012, MOD)

Countersinks for countersunk head screws

Connections with waisted stud - Tape classification

Flared couplings - Flared end

Hexalobular internal driving feature for bolts and screws

Knurl

Drill diameter for use prior to tapping screw threads

Square and rectangular keyways

Woodruff keyways

General purpose bolts and screws - Radius under the head

Center holes

Rivet Shank Diameters (Except Blind Rivets) [ISO 1051:1999]

Stress area and bearing area for threaded fasteners

Countersunk flat head screws - Part2: Penetration depth of cross recesses

Offset cruciform recess fro rotary fastening devices

Clearance holes for rivets

Hot-rolled channel steel

Hexagon lobuar for fasteners - Type E

Fasteners - Clearanc holes for bolts and screws

Fasteners - Split pin holes and wire holes (ISO 7378:1983)

Countersunk head screws - Head configuration and gauging

Cross recesses for screws

Fastners - Widths across flats of hexagon products

Self-tapping screws for metric ISO threads - Part 2: Guide values for hole diameters

Thread run-outs and thread undercuts

Tapping screw connections - Guideline values for core hole diameters and use

12 point socket for bolts and screws

60° centre holes - Types R. A. B. and C

Thread rolling screws for ISO metric thread guidelinge values for hole diameters

Thread ends and lengths of projection of bolt ends for metric ISO threads according to DIN 13

Knurle

Connections for hydraulic fluid power and general use - Ports and stud ends with ISO 261 metric threads and O-ring sealing - Part 1: Ports with truncated housing for O-ring

Hexalobular internal driving feature for bolts and screws

Connections for general use and fluid power - Ports and stud ends with ISO 228-1 threads with elastomeric or metal-to-metal sealing - Part 1: Threaded ports

Dimensioning and indication of knurling

Fasteners—Ends of parts with external ISO metric thread

Connections for general use and fluid power - Ports and stud ends with ISO 228-1 threads with elastomeric or metal-to-metal sealing - Part 4: Stud ends for general use only with metal-to-metal sealing (type B)

Hexalobular internal driving feature for bolts and screws

Geometrical product specifications (GPS) - Indication of surface texture in technical product documentation

General purpose bolts and screws─Metric series─Radii under the head

Rivet shank diameters

Aerospace - Spline drives - Wrenching configuration - Metric series

Connections for general use and fluid power - Ports and stud ends with ISO 261 threads with elastomeric or metal-to-metal sealing - Part 1: Threaded ports

Connections for general use and fluid power - Ports and stud ends with ISO 261 threads with elastomeric or metal-to-metal sealing - Part 2: Stud ends with elastomeric sealing (type E)

Connections for general use and fluid power - Ports and stud ends with ISO 261 threads with elastomeric or metal-to-metal sealing - Part 3: Stud ends with metal-to-metal sealing (type B)

Connections for general use and fluid power - Ports and stud ends with ISO 725 threads and O-ring sealing - Part 3: Light-duty (L series) stud ends

Countersunk flat hed screws—Part 2:Penetration depth of cross recesses

Fasteners—Surface discontinuities— Part1:Bolts,screws and studs for general requirements

Fasteners—Surface discontinuities— Part3:Bolts,screw and studs for special requirements

Internal drive, offset cruciform recess (Torq-Set) for rotary fastening devices. Metric series

Fasteners—Thread undercuts for external metric ISO

Cross recessed-H type

Cross recessed-Z type

Countersunk head screws—Head configuration and guaging

Fasteners—Hexagon products—Widths across flats

Fasteners─Clearance holes for bolts and screws

Thread run-out for fasteners with thread in accordance with ISO 261 and ISO 262

Copper tubes of circular section - Dimensions

Hexalobular internal driving feature for bolts and screws

Stress area and bearing area for threaded fasteners

General purpose bolts and screws - Metric series -- Radii under the head

Straight cylindrical involute splines -- side fit -- Generalities, dimensions and inspection

Knurling

Automatic Cold Header - Hole Size

Recess Dimensions for Flat 82° Countersunk Head Screws

Dimensions of Threads and Points for Types BF and BT Thread-Cutting Tapping Screws

Dimensions of Threads and Points for Type D, F, G, and T Thread-Cutting Tapping Screws

Dimensions of Type TRS Tapping Screws

Standard Test-Plate Thickness and Hole Sizes for Drive-Test Inspection of Tapping Screws

Dimensions of Alternate Styles of Points for Thumb and Wing Screws

Hot rolled flat steel bars and steel wide flats for general purposes - Dimensions and tolerances on shape and dimensions

Cold Rolled Uncoated and Zinc or Zinc-Nickel Electrolytically Coated Low Carbon and High Yield Strength Steel Flat Products for Cold Forming - Tolerances on Dimensions and Shape

Aerospace series - Installation holes for inserts, screw thread, helical coil, self-locking - Design standard

Countersunk head screws - Head configuration and gauging

Tapping rivats - Thread and end

Fasteners - Clearanc holes for bolts and screws

Cross Recesses For Screws

Standard Test-Plate Thickness and Hole Sizes for Drive-Test Inspection of Tapping Screws

Dimensions of Threads and Points for Types BF and BT Thread-Cutting Tapping Screws

Dimensions of Threads and Points for Type D, F, G, and T Thread-Cutting Tapping Screws

Type TRS Tapping Screws

Dimensions of Hexagon Sockets [Table 18]

![Body and grip lengths for socket head cap screws [Table 4]](https://imgcc.164580.com/upload/48/pic/2021/05/27/1622102178590886964.jpg)

Body and grip lengths for socket head cap screws [Table 4]

Metic threads and points for tapping screws

![Type BF and BT, Thread Cutting Tapping Screws [Table 7]](https://imgcc.164580.com/upload/48/standard/2020/06/05/1591322143016742879.jpg)

Type BF and BT, Thread Cutting Tapping Screws [Table 7]

![Type D,F,G and Type T Thread Cutting Tapping Screws [Table 8]](https://imgcc.164580.com/upload/48/standard/2020/06/05/1591326271806674189.jpg)

Type D,F,G and Type T Thread Cutting Tapping Screws [Table 8]

Aerospace series - Six lobe recess - Dimensions and tolerances

Threaded ends of fitting